Safety & Quality

At MOR PPM (PPM), our safety record is no accident. It’s the culmination of years of hard work, discipline, and constantly keeping safety at the forefront of everything we do.

At MOR PPM (PPM), our safety record is no accident. It’s the culmination of years of hard work, discipline, and constantly keeping safety at the forefront of everything we do.

PPM’s company-wide value is to strive for an injury-free workplace. Zero injuries is always the goal.

EMCOR Group companies have earned numerous safety awards, and PPM has earned two Triangle Safety Excellence awards, and have worked millions of labor hours and completed many contracts without a recordable or lost-time injury.

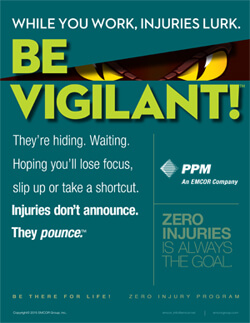

We focus intensely on good work practice to reduce the risk in our work environment and prevent risky behavior. Good performance is achieved when this message is reinforced with our effective and ongoing safety reminder campaign— this time reminding our employees to BE VIGILANT, and that injuries don’t announce…they pounce.

Quality Assurance/Control

The Construction and Field Assembly of Boilers, Boiler External Piping and Pressure Vessels activities are managed to certified American Society of Mechanical Engineers (ASME) standards to insure consistent and repeatable quality.

These facilities management programs also play a significant role in our ongoing efforts to improve productivity. Through careful planning and sound set up, we strive to create a safe working environment and reduce risk. Reduced risk means fewer injuries. And an injury-free project is more productive. EMCOR believes that by integrating safety, quality and productivity in this way, we better support our business and meet our customers' demanding expectations.

By systematically listening to our clients' concerns and developing innovative industrial maintenance programs like these that change the way we work, we increase our ability to provide the fast, dependable, expert power maintenance, pulp and paper construction, and manufacturing facility services our customers need to successfully address their day-to-day challenges, while helping them achieve their most vital business and strategic objectives.

Safety Tools

- Pre-task planning guide

- Customized tool box topics

- "Be There for Life” program

- Professional EHS staff

- Company-wide substance abuse testing

- Progressive disciplinary action process

- Incident, injury, and near-miss reporting number

- Quarterly customer EHS inspections

- National Safety Council first aid/CPR program

- Industrial hygiene sampling program

- Certified rigger/signalperson program

- Certified equipment operators training

- Employee orientation process

- Supervisor leadership training